There are also belts for machines like the can belt. It is very required and it helps us in various ways every day. Belts are belts, we can find them everywhere: fields where there are farmed food, mines for the minerals that come from drilling into our earth and construction sites to build houses. These are also present in our daily lives like that in the supermarket and even at airports. Could belts move things around the map from one point to the other, such as sending packages on a conveyor belt or moving cases in an airport? Have you ever wondered how they are made? Learn how machines form the belts and why this process has developed over time. Baoli is here to help you.

How Can Belts Are Made

Not that making can belts is easy either. They should be heavy-duty belts that can survive. Manufacturers also need to follow certain standards and some rules of making good packaging. However, what this does mean is that they have to utilize materials such as heavy fabrics and rubber, as well all necessary cutting, shaping tools for constructing their belts. This is a place where machines come into play to make work comfortable and easy.

Machines Make It Better

In numerous ways, machines have changed the way belts are imperiled. Congratulations to those of you who can read this on your phone while drinking a cortado, but many years ago everyone was doing everything by hand and it costs time, and lots of times just to be wrong. Still, even your crafted leather belt might prove to be laborious and slow to fashion. Today, machines help us in every step of production and these are effective because everyone knows they work fast and trust it.

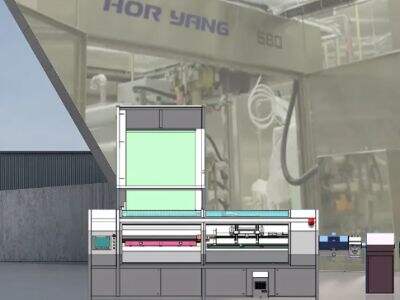

For example, the robots in manufacturing and Cleaning Equipment, production use cases. These robots trim and mold the belts to measure making certain that every little thing is done accurately. They literally run everything, and adjust when necessary. That means less work for the people, and will all go down faster!

These machines have changed the process in two more ways:By using COMPUTERS to control all actions. On the other hand, there is computer model on these computers that can see in real time how produce goes. Make sure machines are working and follow up progress The computers can even help in identifying the causes of several issues long before they turn into serious concerns. So that is kind of what keeps the wheels spinning without any glitches.

Better Quality with Machines

Machines like AGV Forklift have also made it a fair amount easier to produce high-quality can belts. With the new technology, you can ensure that there will be a level playing field and all belts made to the same high standard. Rules and regulations to keep this quality in place. An ISO 9001:2015 is an important aspect in helping you to control and monitor every single process of manufacturing. So, the cans are strong belts that manufacturers can make smooth and reliable.

Faster and Cheaper

Machines and Conveyor have added a new dimension regarding the pace along with money-saving mode of can-tip belt manufacturing, The belts produced in lesser time by means of using machines gives manufacturers a facility to produce more number of belts. To be more clear, they in turn lose less money to the profit of belts. Secondly, Everything is done machines and A machine means no one makes errors due to which productivity increased.

Using New Technology

The making of metal belts, especially can belts are being done by machines. Makers are likewise following the equivalent to help their methodology with the presentation of new innovation. For instance, a greater application of artificial intelligence (AI) in manufacturing. The technology can process all kind of data once it is embedded in to the device, and provide the forecasts about the likely obligations that may materialize in future. AI can help manufacturers to avoid or at least minimize downtime and maintenance inefficiencies.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HA

HA

IG

IG

MR

MR

NE

NE

YO

YO

MY

MY