The tin plate canister that Australia does is of utmost importance. They help to power a large number of businesses and generate many jobs. But preparing the cans for use has always been a more time-consuming and difficult part of things. This can occasionally affect the rate that things are happening in processing plants. Speaking of which, new and improved machines are thankfully aiding to ease this process faster for all parties in the field. Baoli is here to help you.

How Tinplate Cans Are Made

Before we can cover how these new machines like Cleaning Equipment get in on all the fun of can-making, you need to know a little about what goes into making tinplate cans. The process begins with metal sheets. These metal sheets are only thinly coated with tin as a first measure. It is essential as it keeps the metal from oxidising and then rusting, which would otherwise spoil the cans. Then, the sheets are coated and cut into shape to be formed for the body of can and its lid. After being formed, the Pallets, which are essentially large platforms used for transporting goods (in this case packs of cans), have clips placed on top of them.

Workers then need to angle the cans off of the Pallets when it is time for them to be used. In addition to this traditional picking method, is the Depalletizing process. In general, this process is too time-consuming because laborers must perform it manually. They inch each can out, one by one till it drops onto the conveyor tablet. This can be very exhausting and stressful, which is why industrial workers have so much trouble keeping up with their rates.

Supporting Australia's Can Industry

What it will mean is that new machines like Hoist capable of helping with the Depalletizing process should well improve things notably in Australia's tinplate can industry. These machines are designed to pull the cans off of these Pallets at a much faster rate. That being said, this is a huge step up from the labor intensive work that workers have to do before. This frees them up to concentrate on other critical work that is required to facilitate a well-functioning production line.

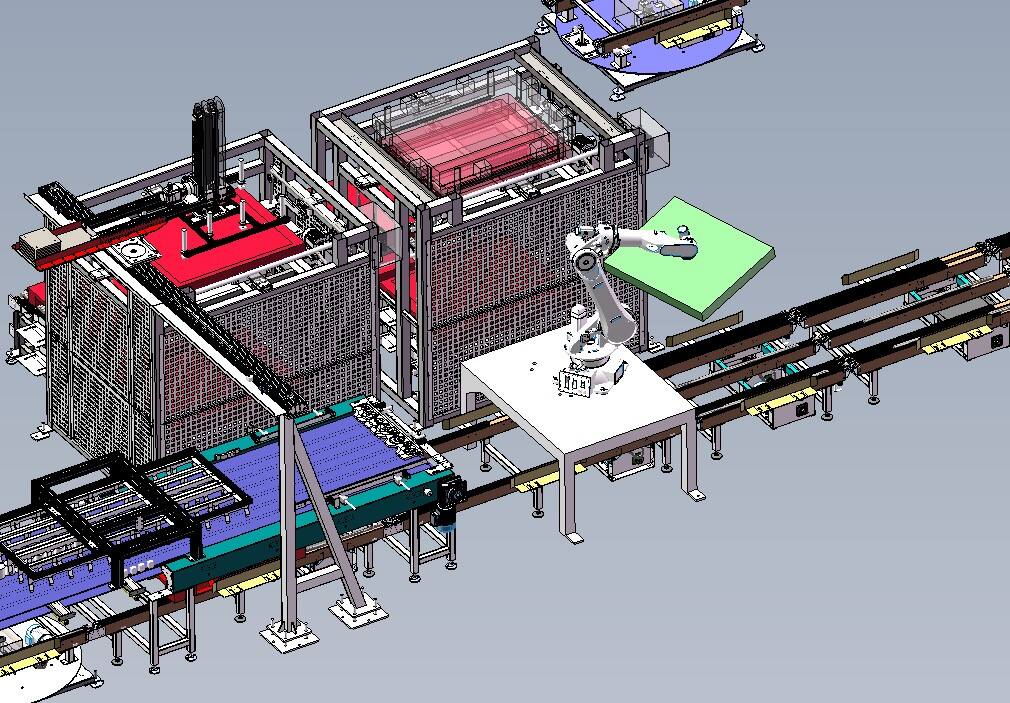

Robotic Depalletizers and automatic can dispensers are examples of these high-end machines that come with different styles. Robotic DepalletizerUnlike a canner, production speed is less of the primary challenge for automating the material handling side. This means that robotic machines are likely not suitable on lines where traditional canned-speed operations take place due to their slower throughput than human-operated units. Automated can dispensers are a convenience that streamlines canned delivery direct to the production line without any human effort required. These machines are capable of shifting cans from the Pallets onto production belts in a speeder and timelier manner. This not only saves time for the worker but also secures them and makes their job easier.

Improving The Condition of Labor

These new machines like AGV Forklift will be made use of for the same thereby benefiting the can industry in Australia on a much larger scale. This allows them to move and process the cans much faster than ever before, which translates into far more cans within a shorter period of time. Which is great as it can help companies get more orders from their customers and hence make them earn more revenue. This could allow for the companies involved to generate higher profits, since their production process would accelerate.

Furthermore, they also make the workplace much safer than before by using these advanced machines. Without as many workers doing the grunt work, there are fewer occurrences where an accident or injury could occur. Thats important because if workers feel safer on the job. Employees are then relocated to other activities where the skill level is higher - sometimes those in which only a human touch and ingenuity can be helpful.

More Cans for Australia

The best part about these new machines is that they can really boost the amount of cans produced. These machines have helped them to produce cans faster and in more quantities. This gives them a distinct advantage in staying abreast of what people want both within Australia and beyond.

Having more cans means the industry can earn more, which allows creating jobsCharsets for people. Companies are able to hire additional workers as they grow and expand, which is beneficial for the economy. Or how when businesses succeed, it can have a positive knock on effect for so many people in the area.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HA

HA

IG

IG

MR

MR

NE

NE

YO

YO

MY

MY