Lots of catgut jobs people did are no longer appropriate for them and can be done by machines. They are increasingly mandatory machines for businesses - in Asia particularly, but worldwide in general - as they save time, make work faster and allow money to be saved too. In the tomato paste industry especially, manufacturers are increasingly using Palletizers or Depalletisers to assist with their production operations. Baoli is here to help you.

The Tomato Paste Industry Palletizers and Depalletizers

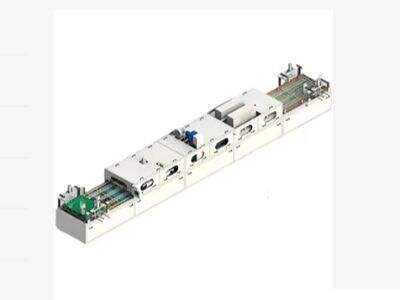

A Palletizer is a device that takes boxes or bags of products and stacks them on top of one another in an even fashion, all placed onto a single flat surface known as a Pallet. Not only that but also it allows the items to stack better which means they can be moved around inside a factory, or loaded onto lorries etc. In contrast, a Depalletizer is another type of machine that does the exact opposite. They remove the boxes/bags from the Pallet. Palletizers and Depalletizer in the tomato paste industry is a great help because it really moves cans of tomato pastes smoothly from one place to another.

What Does the Future Hold for Tomato Paste Cans in Asia?

The use of machines like AGV Forklift for handling cans of tomato paste made in Asia is increasing since the business grows. This process used to be done entirely by hand - workers would manually stack and unstack the cans, a time-consuming task than at times resulted in injury. These tasks are now being carried out by machines such as Palletizers and Depalletizers. The latter change also reduces the risk to workers because companies can now easily move cans around when dealing with large numbers of containers.

Pros and Cons of Machines in Processing Tomato Paste

The use of machines such as Palletizer and Depalletizer for the production of tomato paste, which have many benefits. First off, these machines can accomplish a lot more than the average human in less time. Furthermore, when machines are being used there is little to no injuries among the workers ensuring that everyone stays safe. But at the same time using machines has some disadvantages as well. If you covered the cost of buy machinery, they also need maintenance or repairing can be very expensive. These machines may also require workers to undergo specific safety training in order for them to be used.

Asia: Working better, spending less with machines

Even though the weather companies encounter is tough on their pocketbook, many businesses in Asia still choose to buy machines such as Palletizers and Depalletizers so that they can perform stronger yet overall spend less. Using these machines like Cleaning Equipment, companies can do things better and much faster compare to doing it purely through manual labor. Machines also reduce the risk of injury, making them an important safety feature. As a result, companies can save on labor costs as well. Since technology, especially in Asia continues to develop and machines get even better we can anticipate most companies are going stand on one foot adopt these machines for the manufacture of tomato paste cans. This increasing move toward automation is going to make the industry more productive and operation-efficient in upcoming years.

EN

EN AR

AR

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HA

HA

IG

IG

MR

MR

NE

NE

YO

YO

MY

MY