Is there a location somewhere in Australia with nickel gathering can stacking issues, for example? Don’t worry! Well, fortunately for you we are further here to help but have enlisted advice from experts in the material handling space! So,! Well simple yet quick tips for you to handle this! Baoli is here to help you.

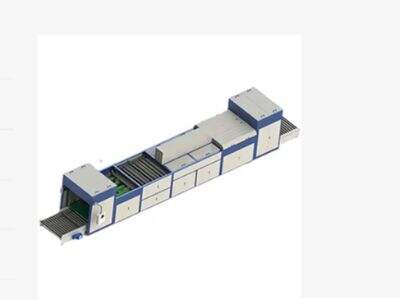

So, What an Automatic Palletizer is?

In basic terms, an automated Palletizer is a machine that will arrange products in individual ways on to the Palletwares. This will cut the time you spent doing it by hand in half. This will save you a lot of time and reduce the risks for making errors. The cleanliness of a Palletizer is key to the reliability and life of your system. One more thing you must ensure is the proper training of employees on how to use that machine. STEP ONE: Confirm they can operate it safety and report any issue immediately. This goes for everything from the quality of Pallets. Down the conveyor line so that Everything runs smoothly you need to make sure this will happen.

Problems in can Palletizing

And the output should be titled as Common Causes If Your Palletizer Is Not Working Properly Indeed, perhaps its simply out of skew with those of the conveyor. Ironically, this is also exactly how foreign material misalignment can enable a specific so type of cans to fall off or stack crooked resulting in catastrophic failures. The opposite issue proof-key is the fact that this Pallet really should not be square and placed effectively so it triggers series jams during the entire unit. Inspect the Palletizer, and check if there are broken components (such as worn belts), that need to be changed. If that ever happens, you should call some professionals to work with your hand and make it strong.

How to Fix Downtime Issues

But what if the auto Palletizer is done reversing itself and you have to do it by hand? This can be a real hassle, this may even get in your way. Here, a few expert tips to tally downtime and keep your machine work snag free. Number one, you definitely want to keep your normal Pretty Fast Now routine on the calendar. It makes you enable to track problems before they go big and turn into bigger mistakes. Second, by all means but don't Forget any spares so you can be ready to fix every broken bits. You will save this much time through out any approach if our machine comes in stop after that we have to pay attention. So, this is the last step that you Do. Of course, this is only going to reduce the problems so you can hopefully resolve them once and for all.

Straya-fy Your Palletizer

Every market is unique, but one of the key issues when it comes to Palletizing tinplate cans and Hoist, especially in Australia. BEWARE: Items to consider when planning an Australian Palletizing SystemSize and Weight of your CansType Of Pallets you are using How fast can the system produce these productsYour Palletizer must be configured and tested for what a market requires in Australia. You can be certain that you require versatile conveyors or a stacking aid and additional tools to make the change in size.

How To Enhance Palletizing Operations

Insights from the Palletizing and Conveyor Pros Below are some suggestions for improving your Palletizing processes, optimized and bulletproof. One of them, as an example: the robot Palletizer. Function Specific AutomationThese automation tools cover an even more of the process and decrease potential human error You can also make use of intelligent software - that which will automatically manage the way your goods are stacked and send a command whether or no everything is okay. Lastly, you might also want to include a Palatalizing expert that can provide custom solutions ideal for your specific need and bring new improvements in the process.

Maintaining automated Palletizers sounds intimidating, but with the above list in mind you can prevent unnecessary stoppages. Take Care of Your Palletizer for Long-Term Operation Clean All the Time Check Things Regularly Decrease Downtime with Mastered Methods Scale as needed Know About Robotic vs Conventional Palletizers Software and System Moisturized Brand These tips are guaranteed to protect your Palletizing job in great shape over the long term so, all is smooth sailing!

EN

EN AR

AR

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HA

HA

IG

IG

MR

MR

NE

NE

YO

YO

MY

MY