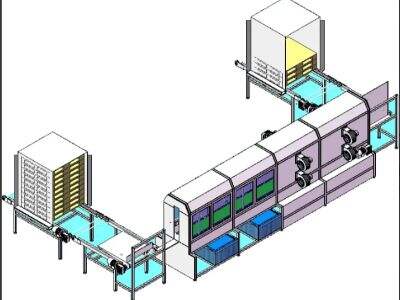

Brazillian factory production milk can cans new Palletizers and Depalletisers machines So the machines are great, right - because they will stack and unstack those cans as you can see below, which I guess means all this work we did used to be done by chaps like these.

They have been able to set up the new technology where a Brazilian factory is producing them multiple times more cans of milk powder like from Baoli in hardly any time and such baselines also allow for far greater consistency, crucial as we are talking about measuring quality. This meant a quicker build of the cans AND one that was not as error-proned... which is a good thing for everyone.

Palletizers and Depalletizers Explained

Some examples are Palletizer and Depalletizers that have been identified as more likely to exist in Brazil due to the powder milk process. In a video to Sobeys shareholders, Longtin explains the machines push cans of milk powder together and buff them into small columns before sorting another way. like boxing gloves side-stacked. This was a huge improvement over the previous method - which required significant time and labor as well as dozens of can-stacking workers on stage.

Those machines when today, allow factories to produce millions of more cans and equally important! its ten times safer than being an employee having a lift thousands upon thousand-lbs every day. This, in turn will lead to a more safe and efficient working environment.

Brazil Shows That Automation Can Be Successful

For the milk powder industry in Brazil, using Palletizers and Depalletizer or AGV Forklift is a wise choice to apply machinery into supply chain. They maintain their competitive edge while integrating the new machines.

The rest of the factory in Brazil is also starting to roll out machinery and modern technologies such as robots, accordingly. These improvements are being shared with virtually every industry, changing the way factories produce and making them more efficient by increasing automation and improving the quality of production.

Machines Ensuring High Productivity and Quality

The American giant has Brazilian factories with machines like Cleaning Equipment that stack and unstack the cans. They check cans for quality control (making sure that's they meet a set of specifications. Least errors making machines and low wastage of material during manufacturing process.

One more benefit of these machines are they work continously without break, food etc This enables the manufacturers to reduce their time and more cans can be made in same duration. These machines are able to make Brazilian factories more qualitative (through making similar conditions for it) so will spend them less and they would earn.

Brazil and Beyond: Which Automation For What?

More and more machines have arrived in Brazilian factories This is a perfect investment of cognition being employed on jobs that are productive. TakeawayPicSolutions has been providing as many technologically advanced welding factory solutions to be found around the world - including our home where owners are demanding new, higher efficiencies in production every day.

Furthermore, automation can boost the expansion of certain industries with more jobs and economies. If the recent spate of innovation and technological adoption at these Brazilian factories is anything to go by, they could end up not just being heavily featured on Brazil but might have a major role in defining what manufacturing of tomorrow really looks like across the world.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HA

HA

IG

IG

MR

MR

NE

NE

YO

YO

MY

MY