Do you like tomato paste? Perhaps you enjoy cooking with it - did anyone know that can of tomato paste in the back of your pantry was probably stored inside a high-tech smart warehouse somewhere miles away from its destination like South Korea? A smart warehouse is a unique kind of storage place that uses the latest technology to store and move products in an efficient manner. This article explains through words what we can learn about the use of an automated Palletizer machine from Baoli in South Korea for tomato paste cans logistics.

How Technology Is Improving Logistical Processes

We use the term logistics that encapsulates how products and goods are planned, implemented, monitored or delivered from one point to another. Inasmuch as this reason holds, the quality of logistics is paramount to business because timely deliveries ensure that products get across to clients when they need it. A lot of logistics work used to be manual Back-breaking manual work that could take hours for workers to do. That being said, a lot of the conventional processes to achieve release management are currently mitigated by modern technology making them far easier and more streamlined for companies using this tech.

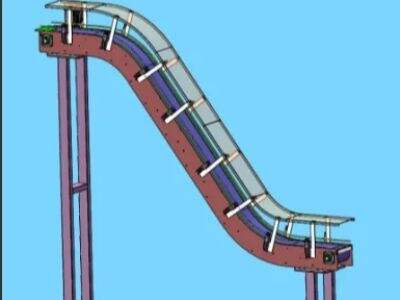

An automated Palletizer is a modern machine that helps in this process. This machine actually stacks the things on a pallet by themselves with people not having to do anything at all. Automation Palletizers: A Game Changer in Warehousing and Storage of Goods Sleek to function and little call for guides tends in manufacturing; Palletizing solutions robots keep you greater time, personnel and mistakes.

Warehousing Efficiency and Cost Savings

Warehouses are facilities that follow a series of steps to store and move goods appropriately. These steps include the fulfillment individual receiving new product, placing it in bins on shelves properly, picking and auditing products for orders that need to go out like something you ordered from Amazon Prime or The North Face website, then shipping these packages off. All of these steps take a lot of time and need huge human efforts. But since the advent of machines such as automatic Palletizers, businesses are able to operate with a swiftness that also translates well into money.

Automated Palletizers orConveyor can work day or night without a lunch break because they are in fact robots! This suggests that they can be used to move a lot more products in much less time compared to human workers so, when coupled with overall lower operating costs of the equipment after all associated initial expenses are considered (as covered in our previous article), these systems might well become cheaper - per parking space delivered across their expected working life at least. This makes them very cost effective, enabling companies to run more products with fewer workers. This is bad for business and resulting in high prices to customers as well.

Revolution in Tomato Paste Can Logistics

The Tomato Paste Can Logistics in Automated Palletizers Previously, workers were required to do this manually and that was not only time consuming but also very exhausting. Recovered by the workers cans must be stacked to allow them to automate Palletisers now do it for them saving a lot of time wasted effort on their part.

One of the big advantage if using this machines is they keep your products safe. Without using an automatic system, cans may be dropped or stacked on top of each other and could lead to damage. In the automatic system, machines stack cans neatly and in an organized manner. The gentle handling also allows the cans to reduce moving about and reduces spillover in movement, which could cause damage.

When South Korea is Scheduling For Smart Warehousing

South Korea is one of the more technologically advanced nations in the world. Now, they are leading the way in smart warehousing. South Korean companies like those in the ECS manufacturing sector, for instance, are working on becoming innovated and more capable through tools such as automated Palletizers with Cleaning Equipment.

Apart from automated Palletizers, the firms in South Korea are also using what is known as warehouse management systems (WMS). These systems provide the facility for monitoring and even control of warehouse operations in real time helping a lot. WMS software helps companies organize their warehouses, control inventory levels and detect how goods are moved throughout the warehouse. Having real-time visibility of everything in progress enables companies to respond smartly and immediately if needed.

South Korea’s New Ideas

Such innovative smart warehousing ideas don't just end with automated Palletizers and WMS in South Korea. They are also investigating the use of autonomous vehicles - machines that can move products around a warehouse, without any human aid. This results in rapid, agile movement of products without the need for a human.

South Korean companies may use drones to check the inventory and move goods throughout the warehouse. Drones can float in the skies and aid with flying around making everything is put into place, saving even more time and work.

Furthermore, South Korean companies are also using data analytics to analyze their operations and see where enhancements can be brought in. Bottlenecks are places where things slow down, and analyzing data can show companies where they need to make adjustments in order to improve efficiency.

EN

EN

AR

AR

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HA

HA

IG

IG

MR

MR

NE

NE

YO

YO

MY

MY